Jim Burchette restored an old glass rod - stripped and rebuilt it - and it came out as good as new

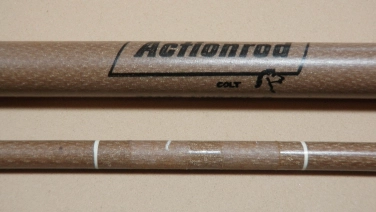

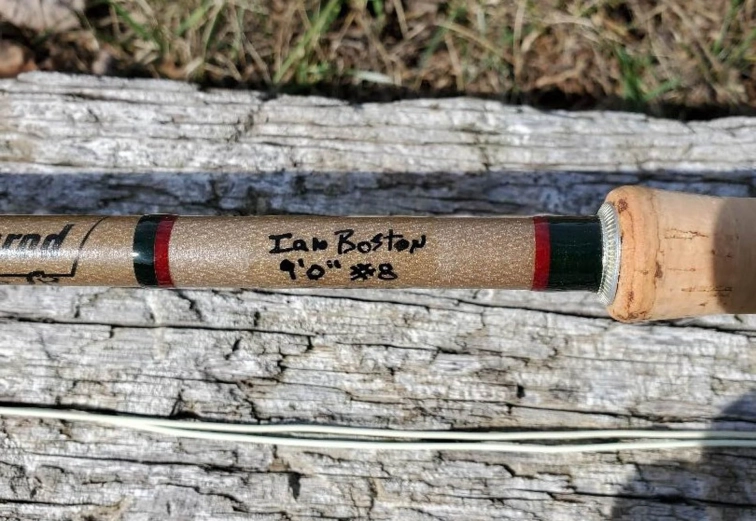

This is the story of a well used 9’0”, two-piece, eight weight glass fiber fly rod, which was given as a gift to a young, budding fly fisher, passed on from a grandfather to a grandson, but with a lot of love and attention given by the author before handing it over.

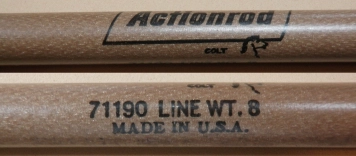

Actionrod

Researching the Actionrod name led to confusing results and timeline. None the less, the company produced many types of fishing rods and fly rods of varying qualities.

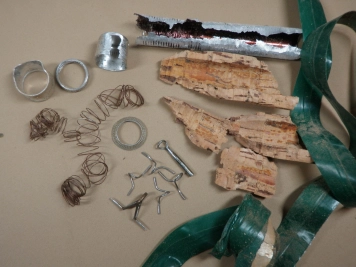

Remnants of the disassembly

Thread and guides removed

Citristrip applied

Stripped rod is complete!

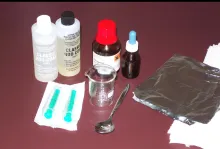

Components for restoration

Jim Burchette

Restoration notes

Thread wrapping and finish notes

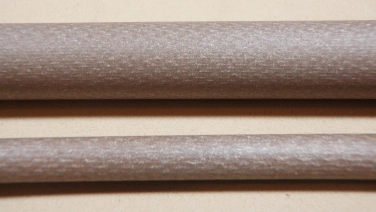

Gallery of the Finished Product, JB 123-23

Results

A standard WF8F taper line was used for lawn casting. The 8-weight line loaded the rod nicely, not under lined and not over lined, just perfect. This nine-foot rod has a slow action, but casts very smoothly and is quick dampening. The rod is a bit tip heavy and an overall weight that you feel in your arm after a lengthy casting session. I feel the upgrade in numbers of guides and modern placement complimented the results of this build. Most likely, the original five guides used in the commercial build of this rod were selected out of economics and not functionality.

Dear Ian,

Your Grandpa Randall brought me this rod to inspect before he gave it to you. One thing led to another, and I ended up refinishing the entire rod. I put on a new reel seat, cork grip, and wrapped new line guides. I am proud of this reconstruction and hope you will enjoy learning how to fly fish with it. My first fly outfit was a was a fiberglass rod with a Pflueger Medalist reel and was given to me sixty years ago when I was 13 years old.

Your rod is fiberglass, it is nine feet long, and is rated for an eight-weight fly line. Fly rods are made for specific fly line weights, not pound weights like a spinning rod which can be for 2-4 pound line or 15-20 pound line. Your rod is more suited for bass and general warm water fishing. It is too heavy for most trout fishing. Meaning an eight-weight fly line cast on a small stream would most likely scare the fish. However, the rod will be good to learn fly casting and line control and will be a lot of fun to catch bass and bream with!

I have put together for you a box of flies, leaders, and a Pflueger Medalist reel with a “weight forward” taper 8 weight floating fly line from my collection. The Medalist reel is set up for left hand retrieve which is normal for right-handed casters. If you are left-handed, I can reverse the line and reel drag for you. The other reel is a South Bend automatic reel which came on the fly rod. I put an extra line on that reel for you. It is lighter than the 8-weight line on the Medalist reel. I’m not sure what weight, maybe a six or seven weight line. I tried it and your rod will cast it, but there is a lighter action. Take care of your tackle.

Fly fishing has been a lifelong passion for me and I find it very rewarding. Any fish that swims in freshwater or saltwater is fair game on a fly rod. Not just trout. Once you catch a fish on a fly rod, you will notice the difference and hopefully, will become ‘hooked’. Fly rods can be made of fiberglass, graphite, and bamboo. Each material has its own casting characteristic. I enjoy the slower and smooth casting style of fiberglass and have numerous glass rods in my collection.

I invite you and your Grandad to come to my house. We can have a casting lesson and talk about fly fishing, knots, and fly tackle.

Included with your rod and reel is a fly-fishing handbook that can answer questions you may have. Some sections of the book are technical. Don’t let it intimidate you. The book gives a good introduction to fly fishing and in time, it will all come together.

I’m sure you are proficient with fishing line to hook/lure knots (most likely clinch or improved clinch knot). These will work with most flies, but there are a few more needed in fly fishing such as a perfection loop and the double surgeon’s loop knot. The double surgeon’s knot can also be used to connect two pieces of monofilament or fluorocarbon line together. A double surgeon’s knot is nothing more than two overhand knots. If you can tie your shoelaces, you can tie that knot. Practice knot tying at home, so you don’t become frustrated trying to learn them when you are fishing. Of course, I am more than glad to show you some simple knots that will get you through 95% of your fishing needs. If you have access to YouTube, there are many good knot tying and fly-casting videos available.

A brief note on fly-fishing leaders. They can be a one-piece drawn leader that is factory made thicker at the butt end and tapers to a smaller tip where you attach a fly. Leaders can also be made by connecting different sizes (larger to smaller) of monofilament or fluorocarbon together. The heavy leader butt connects to the fly line, usually with a loop-to-loop connection. The “tippet” is the thin end where you tie on your fly.

Imagine you have changed six flies throughout an afternoon fishing session and your leader tippet has become shorter and fatter and needs to be replaced. This is when you will attach a new section of tippet material with a double surgeon’s knot. I use Zebco Omniflex monofilament. A large spool can be found at Walmart for $3.00 and will last you a long time. Monofilament floats, fluorocarbon sinks.

Don’t be intimidated by fly casting and fly fishing. It can be as simple or as complex as you want. Make it fun. You will learn as you go, and I am here to help.

As we say: “tight lines”

Jim Burchette

Jim Burchette

- Log in to post comments

Fly rod restoration

I am the grandfather in this story. An old friend gave me this rod to give to my grandson Ian just to introduce him to fly fishing. I took it to my friend Jim Burchette to more or less give me some information about the rod and reel BUT Jim is a perfectionist and now you see what my grandson has. It’s beautiful and I’m sure it will be well used! Thanks to Jim Burchette

Restoration

Just WOW! Great story, that is an inspiration for me. Congrats to Jim Burchette for the artistic work!

Restoration

What a great tribute to memories on the water from GrandFather to Grandson. This rod was is incredibly beautiful not only in the fit and finish JB has facilitated but also in having a soul that can be carried on for generations to come. You are a very talented and paid attention to every detail JB, the thought and consideration you put into the rod building process is simply phenomenal.

Restoration

Thank you all for your kind words. It was a labor of love and hopefully, will plant the seed in young Ian for a lifetime of fly fishing.