It makes sense to have a standardization, which would eliminate much of the confusion that surrounds fly tying thread today.

Some of the issues discussed here, spawned the article Fly Tying Thread Blues, and are covered in depth and with newer information in that article.

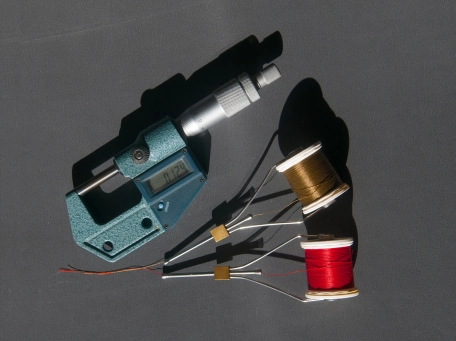

In the summer 2004 issue of Fly Tyer, author Lyle Morgan addressed the question of whether standardizing thread size would help tiers become more effective in producing beautiful and effective flies. It certainly makes sense to have standardization which would eliminate much of the confusion that surrounds fly tying thread today. Based on the fly tier web poll conducted in the same issue as Lyle’s article, voters overwhelmingly agreed ( 252 to 32) that thread should be standardized. The process has begun and over the next few years you will begin to see the denier (pronounced DEN-yer) number listed on most of the spools of the major thread distributors. The denier system of count or weight for silk was introduced in France in 1535. The term is derived for "denarius", a coin from Caesar’s times against which lengths of silk were balanced or weighed.

Manufacturers say

Tom Schmuecker of WAPSI started the denier information process by introducing WAPSI UTC 70 and 140 denier thread in 1998, followed later by 210 and 280 denier nylon thread. His purpose in using the denier number rather than the "aught" rating was to try and subtly suggest that this system was more beneficial to the tier than the "aught" system that had existed for more than seventy years. Denier is also a recognized and accepted standard of measurement among thread manufacturers and the garment industry.

The late Jean-Guy Cote’ of UNI-Products was already putting the denier on a number of his products. He stated, however, " I won’t put the denier on the 8/0 thread until I am sure that all of the other distributors are using the same measurement system to identify the denier of their thread". The successor management is continuing to use the denier rating and I am confident that he will eventually put the denier on the 8/0 spools. Uni already identifies the denier of all their products in a chart which is available to anyone.

Paul Black of Gudebrod stated, "I have already started to put the denier number on the labels of our thread since we do all of our printing in house". Of course, this process may take a year or more to complete given the number of thread sizes (7) and the multitude of colors. These new labels will begin to show up in fly shops gradually as the proprietors order new stock. ( Editors note: In November 2006 Gudebrod discontinued the manufacture and distribution of all fly tying threads. However, good supplies remain with many dealers)

Danville manager, Dan Bezanson, stated, "wherever possible, Danville will include the denier on the spool label." A few labels may not contain the denier due to unavailable space. Danville recently introduced a 140 denier thread that does not have an "aught" designation.

Giorgio Benecchi Products, of Modena, Italy, does not have labels on their spools. However, they do provide this information freely to shops or distributors. In my own shop, I use a rubber stamp to put the denier as well as the "aught" rating on each spool of Benecchi thread.

A little bit of history

Historically the "aught" system began in the late 1930’s . Dan Bezanson said, "Based on the information that has been handed down in the company, Danville Chenille implemented the "aught" system to help standardize fly tying thread. This was based on a system where the number 0 or "aught" was the base point and as the thread became smaller additional zeros were added indicating that the thread was finer. As an example, a thread with six zeros (000000) translated to a 6/0 thread. As other thread distributors came into the market place after the early 1960’s , they followed the same system which was assigning a standard that does not necessarily provide as accurate a measurement for the fly tier as denier.

As more thread distributors and brands became available, the accuracy of the "aught " became muddied.

The aught system has caused much confusion with tyers for many years thus prompting the initiation of the use of denier by WAPSI FLY

When only one distributor existed making some sense of the system wasn’t difficult. Now there are at least seven distributors of thread in what has become a very competitive market. It occurred to me in the mid 1990’s that some of the aught numbers being assigned to some thread was a matter of trying to gain a competitive edge rather than providing accuracy for the fly tying customer. That is precisely what generated the article I coauthored with Bill Merg in the summer 1996 issue of Fly Tyer entitled "Testing the Ties That Bind" The focus of this article was on a number of aspects of thread but emphasized breaking strength and thickness.

Denier

Denier is defined as the weight in grams of 9000 meters of nylon, polyester, rayon thread, etc. There is a correlation between denier and breaking strength of nylon and polyester thread. The smaller the denier number the lower pound/ounce breaking strength of the thread. At the present time, about the smallest denier nylon or polyester for fly tying thread is 40, which would be used for tying midges. The one exception to this denier vs. breaking strength rule is that gel spun polyethylene thread is two to three times stronger than nylon or polyester thread of the same denier.

Denier is only one factor the tier should take into consideration when selecting a thread. The type of material of which the thread is constructed should be considered, whether the thread is a continuous filament, simple twist, bonded, or a rope type. Nylon has about 25% stretch, polyester around 15% stretch, and gel spun only 3% stretch. The type of material being used on the fly as well as the appearance desired also has to be considered. It is important to experiment with all of the various threads available to gain a complete understanding of the pros and cons of each.

Bill Merg conducted the tests on 15 threads that have become available in the past several years.

All of the other data listed in the chart (see next two pages) is from the 1996 test results. He used the same methodology in testing the various new threads that have become available in the past few years as the tests conducted for the thread listed in the 1996 article entitled "Testing the Ties That Bind" that is mentioned above. On all of the tests conducted in 1995, the various brands showed remarkable consistency in thickness throughout the spool. That was not the case in a number of the threads recently entering the marketplace. Those that showed slight variation in thickness included: (variation shown) WAPSI 210 (.008), WAPSI 280 (.005), Danville 140 (.006), Roman Moser Power Silk 6/0 (.0012). Keep in mind that one spool was randomly selected and used for these tests.

Another thread article by Ed Engle in the Spring 2000 issue of Fly Tyer entitled "Hanging by a Thread" compares twelve different threads for tying small flies. Then he rates the threads in a manner similar to how Consumer Reports evaluates products. This same article appears in Ed’s book Tying Small Flies. Ed describes the qualities of twelve threads and discusses the characteristics of each.

Darrel Martin wrote an excellent article on thread in the March/April 2000 of Fly Rod and Reel entitled "A Thread of An Idea". He discusses silk thread and its history along with numerous facts about thread sizing, characteristics of the each material used in thread. He also comments on thread pressure applied when tying and characteristics of waxed thread.

Matching the thread to the size of the fly and the material being used is extremely important in achieving both functional and aesthetically pleasing flies. The more a tier understands about all the materials used in tying the fly the more efficient and effective fly tier he or she will become.

Table

Editor's note.: Data from this table and many other sources was compiled into this larger and updated Fly Tying Thread Table

| Thread Brand | Aught Size | Material | Denier | Breaking Strength | Thickness (.000) |

| UNI Caenis | N/A | mono | 20 | 3 ozs. | 1.7 |

| Gudebrod * | 10/0 | polyester | 45 | 9 ozs. | 1.0 |

| UNI | 17/0 | nylon | 40 | 5 ozs. | 2.0 |

| Danville Spiderweb | N/A | mono | 30 | 5 ozs. | 2.0 |

| Roman Moser Power Silk | 8/0 | gel spun | 55 | 2 lbs. 6 ozs. | 1.3 |

| WAPSI 50 GSP | N/A | gel spun | 50 | 2 lbs. 5 ozs | 0.8 |

| UNI Cord | 12/0 | gel spun | 50 | 2 lbs. 7 ozs. | 0.9 |

| Benecchi Ultra Strong | N/A | gel spun | 50 | 2 lbs. 6 ozs. | 1.3 |

| Benecchi Ghost | N/A | mono | 60 | 11 ozs. | 3.0 |

| Gudebrod * | 10/0 | mono | 50 | 2 lbs. 11 ozs. | 6.0 |

| Gudebrod * | 8/0 | polyester | 67 | 15 ozs. | 1.8 |

| Benecchi | 12/0 | polyester | 70 | 15 ozs. | 1.9 |

| Gordon Griffith Shear | 14/0 | polyester | 72 | 10 ozs. | 1.8 |

| Gudebrod * | GX1 | gel spun | 70 | 7 lbs. 1 oz. | 1.1 |

| Danville | 6/0 | nylon | 70 | 11 ozs. | 1.5 |

| UNI | 8/0 | polyester | 72 | 15 ozs. | 2.0 |

| WAPSI UTC 70 | N/A | nylon | 70 | 13 ozs | 1.1 |

| Gordon Griffith Wisp | 8/0 | polyester | 108 | 15 ozs. | 2.2 |

| Gudebrod * | 6/0 | polyester | 143 | 1 lb. 15 ozs. | 2.3 |

| Benecchi | 10/0 | polyester | 120 | 1 lb. 6 ozs. | 2.0 |

| Danville Monocord | 3/0 | nylon | 116 | 1 lb. 10 ozs. | 2.6 |

| Uni | 6/0 | nylon | 135 | 1 lb. 13 ozs. | 2.9 |

| Wapsi UTC 140 | N/A | nylon | 140 | 2 lbs. 12 ozs. | 1.6 |

| UNI Cord | 7/0 | gel spun | 100 | 5 lbs. 9 ozs. | 1.4 |

| Wapsi GSP 100 | N/A | gel spun | 100 | 6 lbs. 15 ozs. | 1.2 |

| Gordon Griffith Cobweb 2 | N/A | polyester | 134 | 4 lbs. 3 ozs. | 4.1 |

| Gudebrod GX2* | N/A | gel spun | 130 | 6 lbs. 8 ozs. | 2.0 |

| Roman Moser Power Silk | 6/0 | gel spun | 110 | 4 lbs. 8 ozs. | 1.3 |

| Gudebrod * | 6/0 | mono | 143 | 2 lbs. 11 ozs. | 6.0 |

| Danville Flat-Waxed Nylon | N/A | nylon | 210 | 2 lbs. 14 ozs. | 2.0 |

| Danville Fly-Master Plus | N/A | nylon | 210 | 3 lbs. | 2.8 |

| Uni 210 | N/A | nylon | 210 | 3 lbs. 3 ozs. | 2.0 |

| Gudebrod * | 3/0 | polyester | 176 | 2 lbs. 6 ozs. | 4.0 |

| WAPSI UTC 210 | N/A | nylon | 210 | 3 lbs. 5 ozs. | 3.2 |

| Gudebrod G * | N/A | mono | 210 | 3 lbs. 7 ozs. | 7.0 |

| Gudebrod G * | N/A | polyester | 330 | 3 lbs. 11 ozs. | 3.5 |

| UNI Big Fly Thread | N/A | nylon | 440 | 5 lbs. 4 ozs. | 3.5 |

| WAPSI UTC 280 | N/A | nylon | 280 | 3 lbs. 14 ozs. | 2.7 |

* No longer produced

- Log in to post comments