Build your own line winder for maintaining your fly lines and getting them on and off the reel. Tom Biesot considers the line cleaning process and use and construction of your own line winder.

Most fly fishermen and women will recognize the following: just had a wonderful day of fishing, then, at the end of the day time to pack up and go home and after arriving there you pick up your fishing gear and stow it away for the next, hopefully, great day of fishing.

|

|

|

|

|

|

|

|

|

|

Fly line care

What we forget or perhaps don't feel like doing is cleaning the fly lines. After a hard day's work the fly line deserves proper protection in the form of cleaning the line and reapplying a protective coat such as a line dressing. Having done this the line will be ready for another day of fishing and the day can start with a clean, smooth and supple line. From saltwater fly fishermen I know that the majority do take better care of their fishing gear and that they will usually wash away the salt residues with water.

However, a fly line will not be cleaned just by rinsing it with water. The salty residue may have partially gone but the line is absolutely not clean, extra efforts will be needed.

The aging process of the fly line

After a day of fishing a thin layer of dirt will have attached itself to the line such as grease, algae and tiny particles of other harmful stuff. If we do not remove these at the end of the day the surface of the line will gradually turn less smooth and supple. This will cause friction between the line surface and eyes and we will have to make a greater effort to cast the line over longer distances. More friction between the line and the line guides is the cause. The dirt may even wear away the line coating which will lead to loss of suppleness and smoothness of the line surface. The process of drying out will eventually cause little tears across the line surface, which of course leads to quicker ageing of the line.

Delaying the aging process

In order to delay the aging process and to be able to start the day with a clean and smooth casting line we have to clean the line and put on a line dressing on a regular basis. It is best practice to do this after each day of fishing. Experience has taught me that this way the line will stay supple and cast longer distances with less effort and will also float higher.

I still have a small quantity of some stuff which contains a softener or plasticizer agent which soaks into the outer layer of the fly line so as to make it supple again. Its brand name is Permaplas. The stuff has not been on the market for some time now because it contained agents which might cause cancer.

It still works great. I take my safety precautions but I still apply it to my lines at least once a year. I use the popular line dressings after every cleaning. If necessary I will apply some extra line dressing halfway through the day to keep the casting smooth.

The use of a line winder device

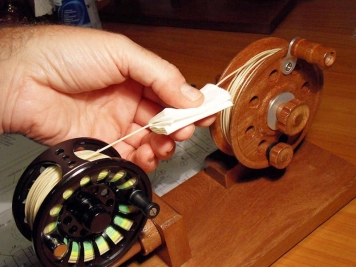

As I will always clean and protect my lines after a day's fishing I developed a system to perform these tasks with a reasonable amount of efficiency.

Not so long ago I would clean my lines using a small electric motor which revolved in both directions with variable rpm onto which I had mounted a drill chuck. I had devised some kind of fixture for this and with the use of an empty plastic line spool with a bolt and nut in the centre which I put into the chuck I was able to wind the line from my reel onto the empty spool.

The reel was attached to the reel seat of an old rod so I could hold it comfortably. As I slowly wound the line onto the empty spool I ran it through a paper tissue which had been wetted with some warm water and some mild soap (baby soap). I then made the electric motor turn the other way around so I could dry the line with a dry tissue. After that I repeated the whole cycle after having applied some line dressing to the tissue and then I removed the excess dressing with another clean tissue. The whole process took about five minutes and resulted in a beautifully clean line for a new day of fishing.

Using a line winder

Some time ago I took another look at what was available on the market concerning devices for winding and cleaning fly lines. After some internet research I found a couple which were suitable for fly fishermen. Prices varied from $50 (Reel-E-Good Line winder) to $290 (Tibor Line master). I felt disappointed at the total number. So there are some for sale, but I have not seen them in the fly fisher stores that I frequently visit. Shopkeepers say there is no demand for these devices. How then, do all these fly fishermen clean their lines? After asking questions at my own club I discovered that cleaning lines was not done a lot. Some would apply some line dressing every now and then. Being a fervent line cleaner myself I was actually quite surprised about this. A remark often heard was that the prices of the fly lines were not that high anymore. Most fishermen buy new ones after two years or so. But cheap lines also need maintenance and should be regularly cleaned. Fishing clean lines gives so much more pleasure and takes so much less effort casting longer distances.

Making your own line winder

Meanwhile I had made up my mind to make my own line winder. Readers of my other article on the Global Flyfisher website know that I have a well-equipped hobby loft with the possibility to perform light wood and metal work.

I initially intended to make a line winder of simple construction which would do what it was supposed to do, namely winding and unwinding the reel lines, also making it possible to clean and dress them.

After having made some preliminary sketches and the drawings I had a simple but effective design, no longer electric but winding by hand. The small size should also make it possible for me to take it along on short fishing trips.

For the sake of this article I chose to make two different versions:

Project 1: a technically more advanced version with enhanced appearance for my own use (I like making that project).

Project 2: a simplified version for the readers who would like to try and make their own line winder with the help of this article.

Full size drawings

Description of the projects

I will first give a brief description of project 1 with the aid of some pictures. It is the more sophisticated one, which I made first. After that there will follow a more extensive description including pictures of project 2: a simple but effective line winder that can be made by most people in a simple way.

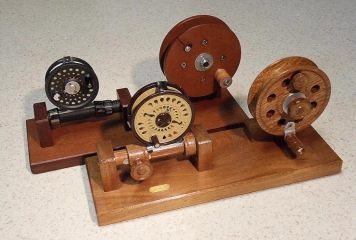

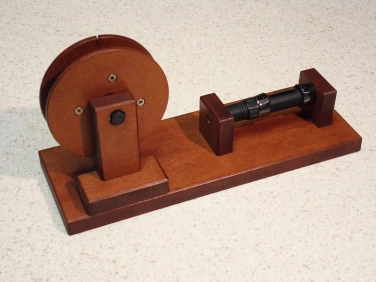

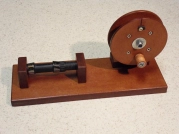

Project 1

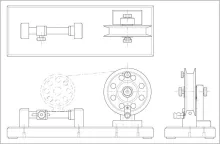

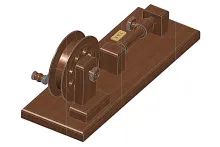

Design and choice of materials for project 1

I have opted for a wooden design with classic looks. I first made the technical drawings (project 1 drawing, project 1 detail), then I selected the materials from the wood I had at my disposal on my hobby loft. While I was digging through the wood pile, I ran into some old Mahogany wood that my granddad had given to me a long time ago. Old, dry and beautiful grain. Nice pieces for this project. It felt kind of special to cut them up after all these years.

Making the line winder

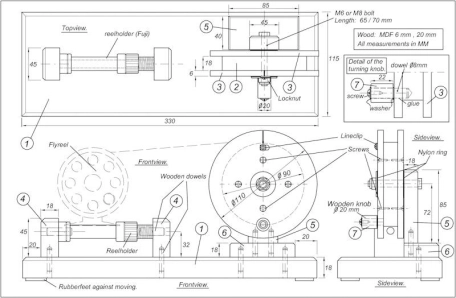

For all important measurements I refer to the work drawing of project 2 in this article.

The whole setup is simple, a winding mechanism in the form of a disc, a reel seat, and some support blocks. I first turned a line winder disc on my small wood-turning lathe, from a massive piece of mahogany. After that I made some decorative holes in the disc with the help of my stationary drill. It sort of gives the disc the appearance of a fly reel spool. I did not yet make the central hole to size. This will be done at a later stage. (see pictures). For measurements see Drawing for Project 2.

Bottom plate and support blocks

These can be easily made from the massive mahogany board. Since I will always make work drawings, this is not hard to do, we simply follow the measurements and after that the sides will be finished with chamfers.

The support blocks will then be drilled for the screw holes and the holes for the reel seat and in the vertical support block a hole must be drilled for the screw which will keep the bearing in place.

The reel seat

Because I went for classic looks I used mahogany for the reel seat as well (in project 2 I will use a factory-made one). As I only have a small wood-turning lathe, the clamping rings and the axle around which they move are not difficult to make. I glued an aluminium bushing inside the movable clamp ring which contains an internal screw thread for a clamping screw.

Fixing the reel seat and rings

I also milled a small level area on the axle and glued a small aluminium plate onto it so the clamping screw will not damage the wood. The rings have been chamfered on the inside so as to pick up the reel foot more easily. The fixed ring has been glued onto the axle and the other one is movable, so we can clamp the reel. On both ends of the axle we will place a dowel (see the picture). The reel seat will be glued between the clamping blocks and then we will leave it for the time being.

|

|

|

|

|

|

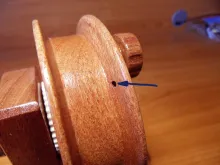

Line winder disc bearing

Since we will wind the line by hand we do not need a high-tech bearing. However we need some reasonable kind of support for the disc. An aluminium axle or some other material with the correct fitting in the wood will do the job. However, being the perfectionist that I am and also because I like to make nice technical things, I opted for the bearing system that I used for my fly reels, the O-ring bearing (see the article Tom's Reel).

On my metal lathe I made a bushing and a fitting axle out of aluminium. In the axle I made grooves for the O-rings and the fittings for the internal and external threading for the clamping screws (see pictures).I drilled a matching hole in the line winder disc on the wood lathe and then I glued the bushing into the disc using epoxy glue. After applying some silicon grease on the axle and the O-rings this provides a perfect bearing. The bearing axle will be tightened by a clamping screw which I made for the purpose. At the other end the disc will be locked by a ring and a clamping screw.

|

|

|

|

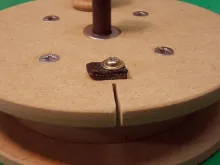

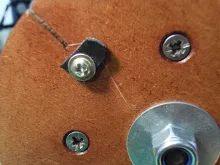

The line clip

So as to be able to attach the leader or line tip onto the line winder disc we will need a line clip. First we drill a slanting hole through which we put the line. I glued a small internally threaded aluminium cylinder in the disc which holds a specially made clamping screw with a rubber ring underneath.

Before we start winding we put the line through the hole then place it under the ring and turn the screw.

|

|

|

|

|

|

A rattle system

Just for fun (it is not strictly necessary) I made a clicker system such as we find them on our fly reels, so that when we wind the line we will hear a professional rattling sound.

I had a small toothed wheel from a "Pritt correct it" tool which I was able to fit to size for the axle so it could be screwed onto the disc. Then I mounted a small pin with a small piece of silicon tubing on the vertical support pad and after I had tuned it I had myself a smooth-running clicker system. For further details I refer you to the article ""Tom's reel"" on this very website and to the following pictures.

The clamping screws

As told before I made all the clamping screws myself. Because I thought the line winder would look better if I made it entirely of one kind of wood (mahogany) I used this wood for the clamping screws as well. They are not that hard to make if you own a wood turning lathe. The grips were milled with the help of a machine and a dividing table. The screw thread comes from bolts from which I cut the head. The headless bolt was then glued into the knob using some epoxy glue.

The turning knob and adapter

If we want to turn the disc we will need a nice-looking small knob made also of mahogany.

We could screw this directly on the disc with the help of a small wooden axle (see project 2). However, I chose to locate it just a little outside of the disc diameter using a small aluminium plate (see pictures and drawing). After finishing we mount it on the disc.

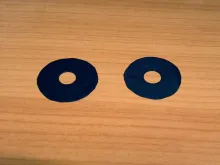

Making plastic rings

We must prevent the disc from making contact with the vertical support pad and the clamping screw so we have to place a plastic ring or metal one which we make ourselves on both sides of the disc when mounting the parts. I will describe the manufacturing of these rings in project 2.

Finishing and mounting

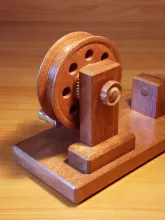

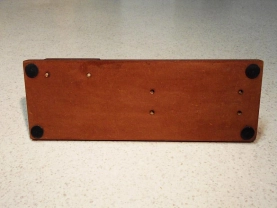

In order to make the natural beauty and grain of the wood come out I finished every part by applying two layers of satin shine varnish. After drying I took my time in mounting all parts for a neat job.

The line winder is now ready to be used. So as to counteract movement on smooth surfaces we glue four rubber feet to the underside of the base plate.

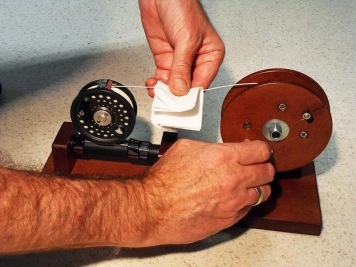

How to use it

We place the reel in the reel seat and pull the leader tip or the fly line through the hole in the disc and clamp it underneath the rubber ring with the clamping screw. As we wind the line we clean it using a tissue onto which we have put some mild soap and lukewarm water. When rewinding the line we dry the line with the help of another tissue. Then we repeat the whole process, this time using a tissue which holds some line dressing of a, preferably, better brand. Rewinding the line again we remove the excess line dressing. The line must now be left for a couple of hours so that the dressing can be absorbed by the line and dry up resulting in a nice, smooth surface.

When we cast the line we will find that it will shoot through the eyelets with much less friction, thus achieving greater distances with less effort.

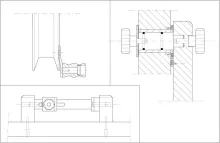

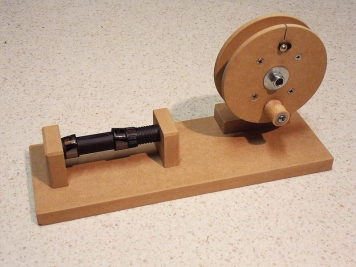

Project 2

In the following chapters I shall give a description of a line winder which is less complex from a technical point of view and therefore easier to construct and it looks great as well. Full size drawing for Project 2.

Design and selection of materials

Starting point for the design was the one just described in the foregoing text.

Due to the simplified construction as well as the use of MDF board which is easier to work I had a line winder that could be made by others for little cost and in simple way using simpler tools.

In the following drawing the most important measurements can be found. This line winder can be used for AFTMA line numbers up to 10. I have not got any lines which are higher in number but if some of the measurements are enlarged, thicker AFTMA lines could easily be used as well.

The total construction makes use of two thicknesses of MDF board, 6 and 18 millimetres. Below I shall try to render a concise description of how this line winder can be made with limited technical means. Those of you who have professional woodworking machines at their disposal can of course use these. And you could use other wood species but MDF is cheap and can be easily found.

|

|

|

|

|

|

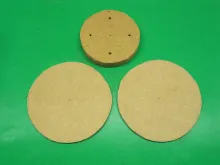

Line winder disc

The large round disc for winding the line consists of three separate discs, two thin ones of 6 mm thickness (post 3) and the centre one of 18 mm. These can be made in several ways. If you own a band saw or jigsaw sawing it should not present a problem. After scribing it with compasses and drilling a centre hole in each disc the sawing can be done. Next we have to sand the discs to achieve the proper round shape. Again this can be done using a sander or by hand.

The two thinner discs (post 3) will then be screwed concentrically onto each side of the thicker disc with wood screws using the centre holes for checking the right position which completes the job on the disc except for drilling the right axle diameter.

For bearing the disc we will use a fitting bolt, a bolt which is partially threaded. The smooth cylindrical part will be used as the bearing surface for the disc.

Since we wind the line by hand, which requires but little force, we can keep the bearing simple and the cylindrical part of the bolt will be sufficient bearing for the disc without causing wear.

I used an 8 millimetre bolt with a length of 60 millimetres and it can be easily had at your local hardware store. You should also get a self-locking nut and two large rings. Other bolt sizes can be used as well, perhaps 6 or 10 millimetres.

The centre hole in the disc will be drilled to the same size as the diameter of the bolt. This must be done with help of a drill press. The hole must go straight through the disc. So far for the disc.

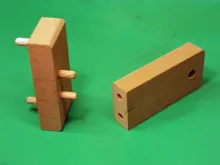

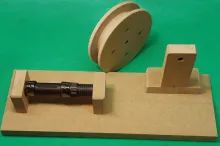

Reel seat

For the reel seat we will use that of an old rod or we buy ourselves a cheap new one. Suppose we have bought one then we must first close the ends with rounded MDF stops. We can glue them with quick drying Epoxy adhesive. We can later screw the reel seat through the MDF support blocks into the wooden stops using wood screws or we can use dowels (8 mm) as I have.

|

|

|

|

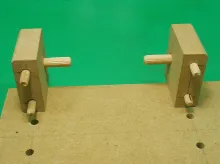

Making the support blocks and the base plate

The support blocks for the reel seat (post 4) and the disc support (post 5 en 6) are not hard to make. We follow the measurements and chamfer the sides for the sake of appearance.

The same holds true for the base plate (post 1), This is a rectangular plate with chamfers on all sides.

Next we will drill an 8 mm hole in the vertical support block (post 5) for placing the fit bolt, see drawings for measurements. The vertical block must now be placed onto the horizontal block

(post 6) with countersunk screws or dowels as I have shown in the drawing and then we screw the lot onto the base plate (post 1) according to the drawing with countersunk screws or dowels. Watch the placing of the disc. It should be in the centre line of the base plate. Mind you, do not glue anything yet!

Attaching the reel seat

Using the measurements in the drawing as a guide we will then drill the holes in the support blocks for the countersunk screws or dowels that we use to attach the reel seat between the support blocks

(post 4 (2x)). Place the support blocks with the reel seat on the base plate as in the drawing. See to it that the reel seat is in line with the disc.

Scribe this on the underside of the plate then clamp the support blocks and drill from the underside for the screws or the dowels. Then clamp everything together temporarily.

|

|

|

|

Making the knob

We still have to make a knob on the disc (post 7). An easy solution would be to screw a cylindrical piece of wood on the disc. However we should not squeeze it too hard when winding. The better solution is a knob which can turn. This can be achieved in several ways. I think the following is a pretty simple but effective solution.

We shall use a standard 8 mm dowel which we glue into the disc. First an 8 mm hole must be drilled. Then glue in the dowel. After that we have to make a cylindrical piece of wood with a diameter of approximately 20 mm. This must then be cut to the proper length which should equal the protruding part of the dowel we have glued into the disc (post 7). Next we have to drill an 8 mm hole in the centre so that the dowel fits into the knob. We proceed by placing a metal or plastic ring with a larger diameter than the dowel onto the dowel using a small wood screw so that the knob cannot come loose but can still be turned. If necessary, we can modify the shape somewhat by placing the knob in a drill with the help of a bolt and then shape it by sanding (see detail drawing and pictures).

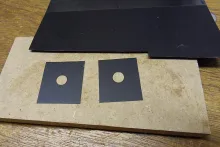

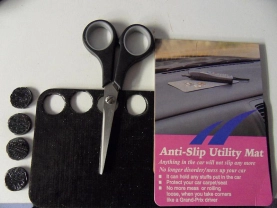

Making two plastic rings

With the help of a piece of nylon or plastic foil having a thickness of about 0.5 millimetres we can make two rings which will see to it that the disc will turn with ease and without friction. We could use the plastic cover of an old folder or something like that. Use a sharp-pointed pair of scissors. The centre hole must be a little larger than 8 mms and the diameter should be around 30 mms.

Making the line clip

When we start winding the fly line we have to attach the leader or tip of the line to the disc. For this we use a simple line clip made from a tiny piece of rubber which we screw onto the disc. Cut a longitudinal piece of rubber size ( 6x12 mms), sand a point at one of the smaller sides and round it as shown in the picture. Use a saw to make a short groove in the flange plate of the disc and clamp the rubber piece underneath by screwing it in such a way that a long side protrudes. Now we can clamp the line and release it with no effort at all.

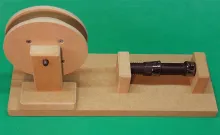

Mounting the line winder

When all the parts have been made we can mount the line winder. The reel seat and the disc support blocks (post 5 and 6) have already been mounted onto the base plate with wood glue. Now the disc and bolt can be mounted.

Take the bolt and first place a metal ring. Put some silicon grease on the cylindrical part of the bolt. Then we push the bolt in post 5 and place one of the plastic rings on the other side. Then we push the disc across the bolt and place the second plastic ring followed by a metal ring and the lock nut. Turn this with a wrench and block the other side also with a wrench. The internal friction of the lock nut makes turning it rather heavy which gives us the opportunity to bring it into such a position that the disc will run smoothly without any latitude. Please, put silicon grease on all turning parts before assembling which will ensure smooth running.

Varnish, stains or wax coating

We can now leave the line winder as it is but we can also choose to apply a finish in an appealing colour.

I put on a coat of wax stain on the MDF line winder. I used a single coat of Briwax, which I applied with a cloth and after allowing it to dry up I used a brush with tough bristles to achieve a nice finish in a beautiful colour (mahogany) as you can see in the picture.

To prevent the line winder from moving when winding the line we must put four small rubber feet under the base plate. I have cut these rubber feet from a sheet of non-skid rubber (see picture).

Using the line winder

The line winder is now ready for use if we place the reel on the reel seat. We take the leader tip which we clamp in the line clip and then we can wind and rewind it with the reel. While winding it we clean the line with a tissue and some mild soap with lukewarm water. The line dressing is applied in the same manner and we will have our lines ready again for another day of fishing.

The set up for this line winder is very basic, so it can be made by those who have little technical knowledge and skills and/or do not possess advanced tools.

However, if you are a skilled technician with the necessary equipment at your hand you could modify some technical aspects and make a more sophisticated job of it.

The cost of the MDF board amounted to 5 euros and the reel seat was taken from an old rod.

The aim of this article was to teach fly fishermen to pay more attention to the maintenance of their lines which can be so simply achieved when using a line winder. And it will be so much more satisfactory if do the job with a tool that you made yourself.

Proper maintenance of the lines will not only make them last so much longer, it will also add so much more pleasure when casting them.

Tight (and clean) lines!!!

Tom Biesot

- Log in to post comments

Hi Tom,

1000 time

Hi Tom,

1000 times thanks for sharing this wonderfull contraption with us!

Build one today!works like a charm.

Kind Regards

Hello Max,

That i

Hello Max,

That is a very nice line winder you have made with the inspiration of my article,

Nice wood and very stylish.

Thank you for sharing and using my article , that is the meaning of it all !

Best regards,

Tom.

Hi, I tried one of

Hi,

I tried one of my personal taste and I published some pics on my flickr photo stream.

Search for: flickr sugomoli photostream

Thank you Tom for the inspiring idea!

Max

Hello Ed,

Thank y

Hello Ed,

Thank you for the comment, but you said that you made one about 70 years ago, can I ask you then, what is your age Ed? I think you must be between 85 and 90 years old at the moment! And still interested in Flyfishing, what is your secret, please tell me!!!!!!!!

Best regards,

Tom.

Nice video. It remin

Nice video. It reminded me of one I made about 70 years ago using a round "Quaker Oats" box. Fly line were very different then compared to hi-tech finishes of today, but cleaning is still important.

This tool looks very

This tool looks very professional. Beautiful handcrafted. If I had the skills and the equipment to make

this tool, I was starting to-day.

Hi Tom,

Very impres

Hi Tom,

Very impressive and interesting, and I think a very good tool for this 'problem'.

I stay by tying Salmonflies, but I love your reels and tools so now waiting for more idea's....

Regards Henk van Bork

That is a really pre

That is a really pretty line winder. However, and old line spool with an installed handle and scrap wood for mounting will do the job. Love the time, effort and beauty but line winding and cleaning is more of a utilitarian function.

Great article! As a

Great article! As a tinkerer that likes to see ideas this way above average. Thank you

A simple way to cut the pieces

I was looking at these pieces and being the owner of some fairly large hole saws I thought that a easy to make the pieces would be to simply use what is normally the waste from when you cut a hole and use them for the round pieces for this project. They will have the same size hole and will be perfectly round. You can then use a bolt the same size as the hole for the axle. If you use a backer board when you cut the circles you should get fairly smooth edges.