Leather maker Remus Stanescu describes the dirty work behind making a couple of Hardy style reel cases.

Italy based leather worker Remus Stanescu has shown us his beautiful craftsmanship before, and recently he contacted me about a project, where one of his customers had ordered a couple of leather cases for some classic Hardy fly reels.

He had decided to shoot an image series of the making of the second one after having realized that quite a lot of work had gone into the first one.

Shortly after I had received the images and text from Remus, Jes Kamp, a good Danish friend of mine, posted some pictures of his newly acquired reel cases online. And yes! They were these exact cases, and by sheer coincidence, it turns out that it was my friend who had ordered these bespoke reel cases for his reels. Jes shot some pictures, and had his brother, who’s a photographer, shoot even more, and you will see those pictures as well as shots done by Remus in this article.

Jes asked me to let people know that he's very happy with these cases, and that they - in spite of the price tag - come cheaper than the original cases, which easily cost 300.- UK£ a piece.

|

|

|

|

Ole Kamp

This is what Remus wrote me:

After I have finished my first Hardy style reel case, I have decided to take pictures of the making of the second. I have to admit that they are incredibly hard to make, and need careful planning and a lot of meticulous work. This is the most difficult leather item I have made so far.

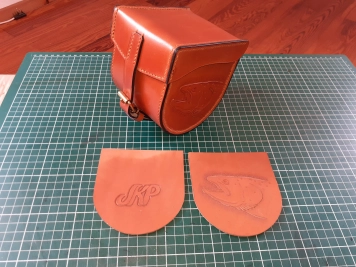

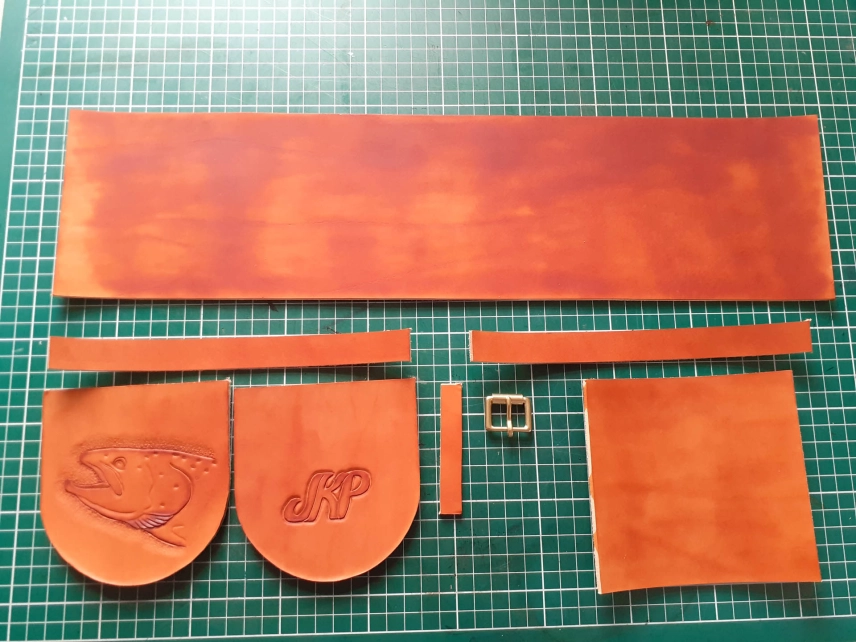

First step: I cut and carve the side parts. Both parts are carved, one with a salmon head and the other one with the owner's name initials, in this case JKP.

I double the sides with 2.5 mm leather to have a strong structure and a good surface to glue the principal part. After that I apply a first layer of dye. The real dye will be made with an airbrush in a "sunburst" effect.

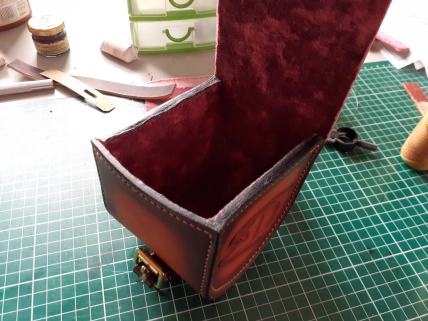

Then I glue the velvet on the inside faces and trim it down.

The next step is making the wood inside and attaching the buckle to the case. And a little airbrush...

The hardware I use is solid brass, made by Abbey in England.

Next comes the sexiest part of the project. Box stitching. Box stitching is the most difficult stitching. In this kind of stitching, you're supposed to make diagonal holes, at 45 degrees, for the stitch. This means that I have to make them at the same angle (45 degrees) with the diamond shaped awl.

After gluing the gusset to the main body I have to make sure that holes meet, and that I can easily pass the needles through.

Of course, the distance between the holes varies, for mathematical reasons. A lot of calculation and practice is required. But the satisfaction when it works, is really high!

Box stitching again! This time the lid. And the case is almost ready. Just one step is missing: the wooden parts inside.

This is the dirty work behind a Hardy reel case. This type of leather case is the best kind to store and protect the reel.

Ole Kamp

Contact

Remus Stanescu can be reached here:

Web site: stanesculeathercraft.com - the site is unfortunately offline.

Mail: stanescu.remus@gmail.com

Facebook: Remustanescu

The price for a handmade, custom made, leather reel case starts at 250 Euros.

Hand picked for this article

- Log in to post comments